2017 wholesale price Steel Shots And Grits - Mechanical Recycling Sand Blasting Booth – DX-BLAST

2017 wholesale price Steel Shots And Grits - Mechanical Recycling Sand Blasting Booth – DX-BLAST Detail:

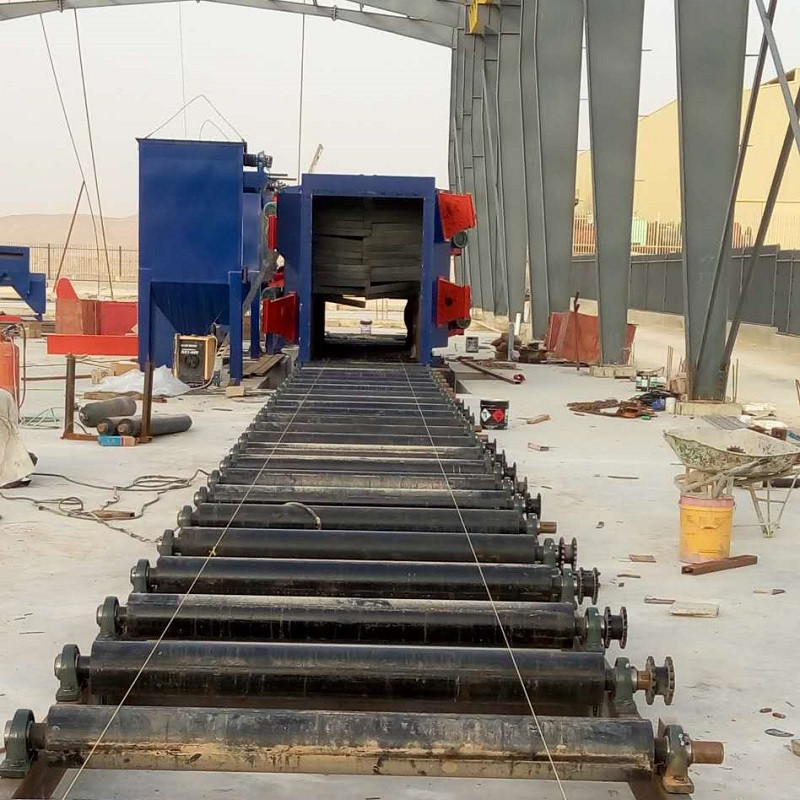

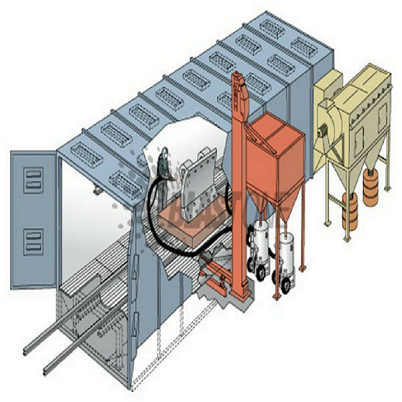

Manual sand blasting booth mainly includes Blasting chamber, Sandblasting tank, Abrasive circulation system, Lighting system, Dust Collector, trolley system, Electric control system and other parts. The surface finish level can achieve Sa2.5.

Blasting body is made of sandwich panel and steel plate, it is a strong, seal and spacious operation space to clean the workpiece. Blasting chamber is consist of body shell, left and right side wall, lateral wall, roof, protection plate, etc.

Technology parameter:

Part I Processed work pieces and parameter

1The sand blasting chamber internal size (L*W*H): 8000*6000*5000 mm

2The sand blasting chamber door size(W*H): 6000*4000 mm

4Max.workpiece weight: 20000 kgs

5Finish levelCan achieve Sa2 .5 (GB8923-88)

6Processing speed:15-30 m2/hour (A-D level original surface material and workpiece cleaning requirements, operator start different blasting guns quantity)

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.

Product detail pictures:

Related Product Guide:

Fentanyl overtakes heroin as the No. 1 opioid overdose killer | Sand Blasting Booth

Man beaten with brick: Woman charged with attempted murder for allegedly beating 92-year-old man with brick | Road Surface Shot Blasting Machine

It is a good way to improve our products and service. Our mission is to develop creative products to customers with a good experience for 2017 wholesale price Steel Shots And Grits - Mechanical Recycling Sand Blasting Booth – DX-BLAST, The product will supply to all over the world, such as: Uruguay, Southampton, Pakistan, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!