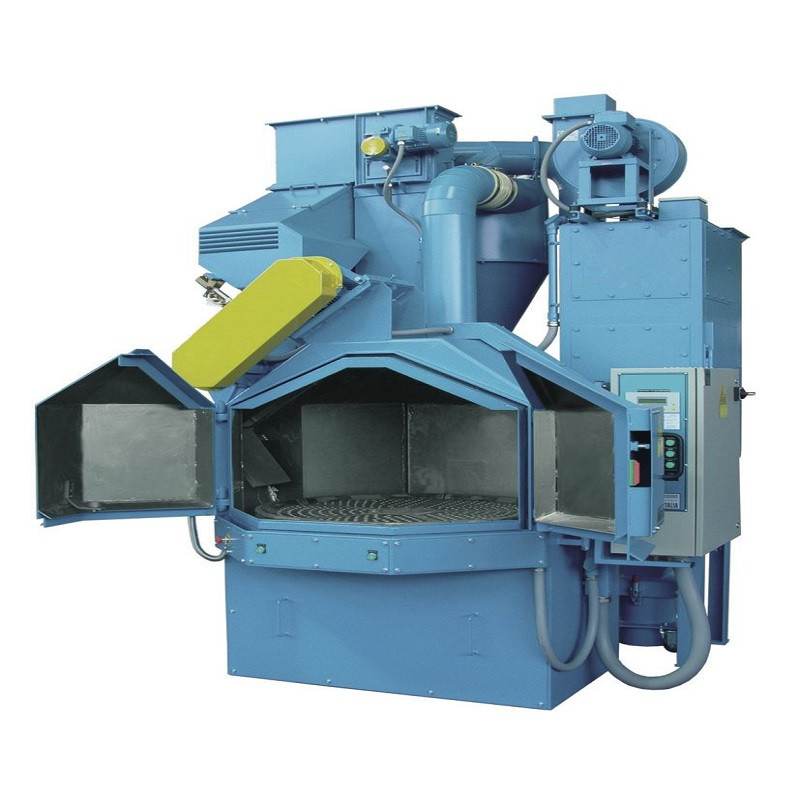

2019 China New Design Turntable Rotary Table Steel Shot Blasting Machine

Our aim should be to deliver high-quality solutions at aggressive rates, and top-notch service to prospects around the globe. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for 2019 China New Design Turntable Rotary Table Steel Shot Blasting Machine, Leading the trend of this field is our persistent purpose. Furnishing 1st class merchandise is our purpose. To make a beautiful long run, we would like to cooperate with all buddies at home and abroad. Should you have any interest inside our products, you should will not wait to get in touch with us.

Our aim should be to deliver high-quality solutions at aggressive rates, and top-notch service to prospects around the globe. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Rotary Steel Shot Blasting Machine, Rotary Table Shot Blasting Machine, Turntable Rotary Shot Blasting Machine, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the “client first” principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

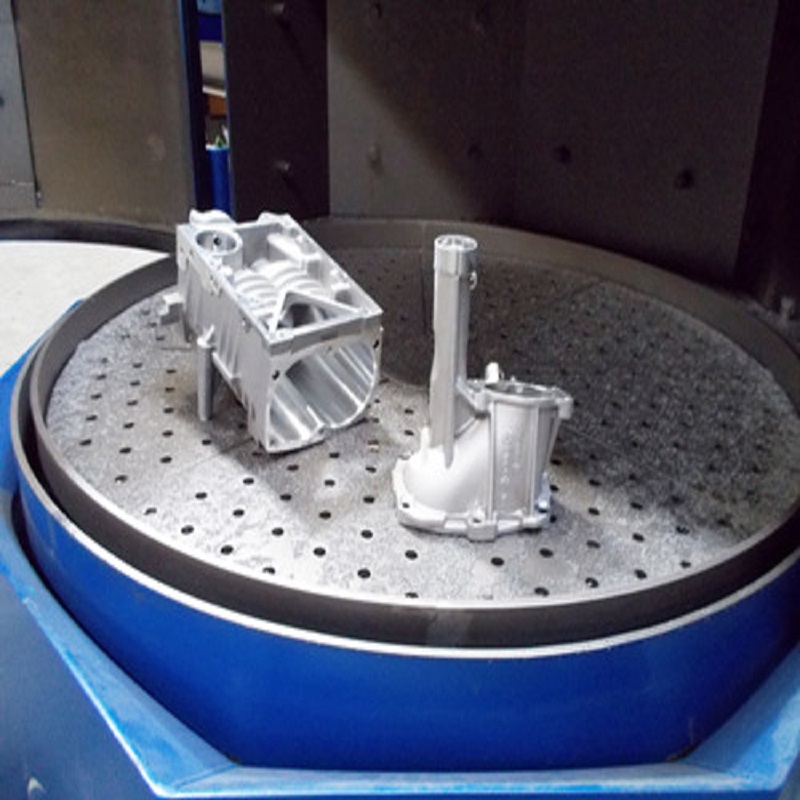

Hot Sale Rotating Table Cleaning Equipment from DX offer total flexibility in your shot blast operations. Whether you are cleaning welded fabrications, cleaning and deflashing castings, or shot peening components, the Rotary table, can help reduce the production time required.

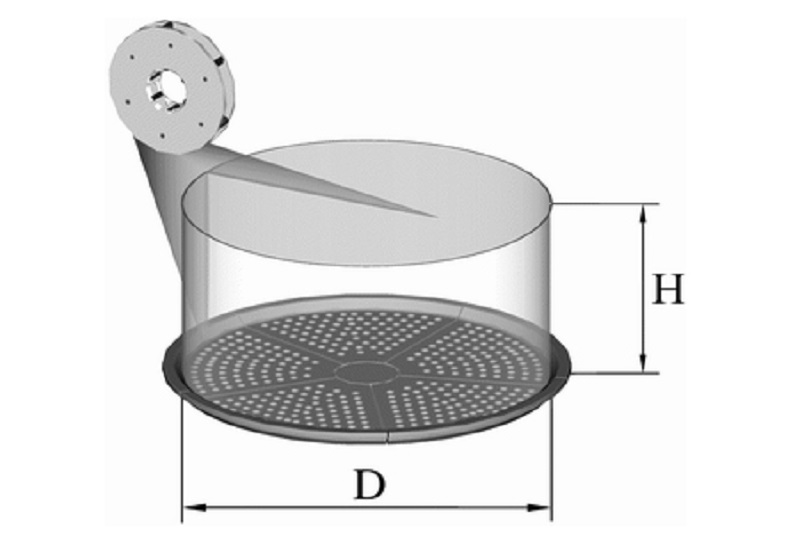

Technology parameter:

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

Applications:

- Cleaning

- Corrosion removal

- Cosmetic Finishing

- Deburring

- Deflashing

- Internal Cleaning

- Paint Stripping

- Preparation for Painting, Bonding and Plating

- Rust and Heat Scale Removal

- Shot Peening

Surface Texturing

Packing & Delivery:

Standard package for sea shipment.

Shipped in 50 days after payment.

Warranty: One Year.

After-sales Service Provided: Engineers available to service machinery overseas.

FAQ:

1). Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2). Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3). Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4). Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

5). Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit.We have never got any complaint from our customers.

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.