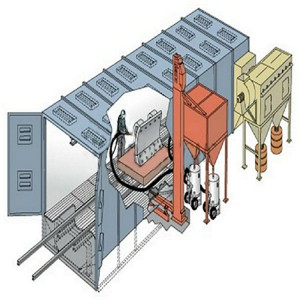

Batch Type Tumblast Machines

Batch Type Tumblast Casting machines (MB) are used for bulk, tumble proof material. The product range includes a comprehensive range of machines for desanding and decoring castings and for descaling forgings or heat-treated work piece. The work piece are continuously tumbled during the blasting process. Our expertise in this field enables the development of customised solutions which can include automatic loading/unloading of workpiece and removal of abrasive residues from the part.

Continuous Tumblast machines (CT) treat the same parts but are situated within either an automated process or a continuous production line. The advantages of this being high performance rates, less or no human contact with parts, and a more speedy, complete process for the parts.

Technology Parameter:

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

Applications:

• Desanding and decoring of castings

• Descaling of castings, forgings and heat treated parts

• Shot peening (without process security)

• Deburring of plastic and rubber parts

FAQ:

1). Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2). Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3). Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4). Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

5). Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. We have never got any complaint from our customers.

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.