Good User Reputation for Aluminum Anodizing Sand Shot Blasting Equipment Machine With Stainless Sand

Our company insists all along the quality policy of “product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation first, customer first” for Good User Reputation for Aluminum Anodizing Sand Shot Blasting Equipment Machine With Stainless Sand, Welcome any inquiry to our company. We will be happy to ascertain friendly business enterprise relationships with you!

Our company insists all along the quality policy of “product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation first, customer first” for Aluminum Blasting Machine, Aluminum Shot Blasting Machine, Anodizing Shot Blasting Equipment, We have been your reliable partner in international markets with the best quality items. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

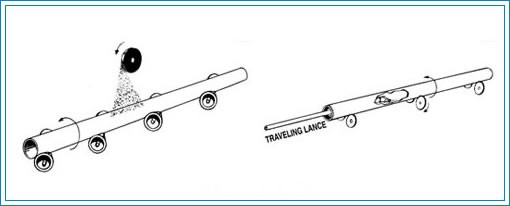

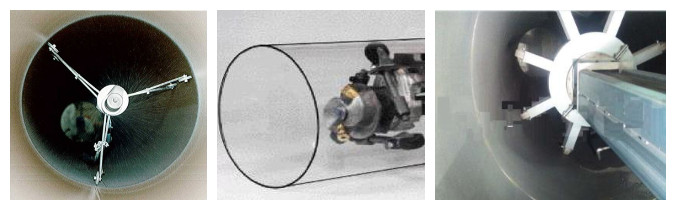

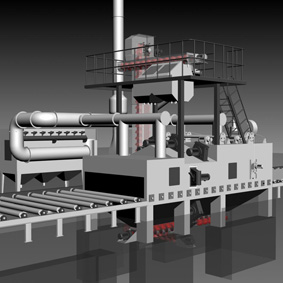

Steel Pipe Inner & Outer Shot Blasting Cleaning Machines are designed for the large, middle and small calibre size of the steel tube(outer and inner) and the cylinder. Impeller head locate at multi angle, This Steel Pipe Shot Blasting Machine is the high efficiency blasting wheels, shot blasting with high-speed thick blasting pills and blowing on the surface to have a tridimensional and omnibearing cleaning, to clean away the rusting layer, oxidation layer and other dirty things from surface quickly.

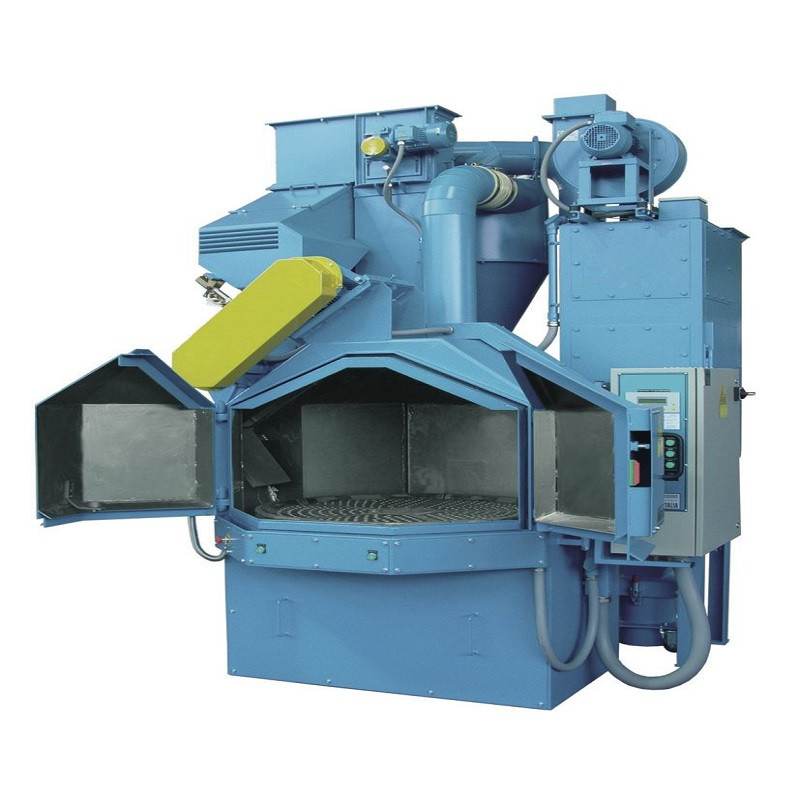

DX blast offers a range of roller conveyors from small simple machines to heavy duty machines and complete preservation lines, which can with 4,6,8,10,12 wheel units.

Machine Details:

1) The number and power of the turbines are chosen according to the requirement production rate.

2) PLC control system, stable quality and easy to get support from local.

3) Component key parts adopt world famous brand, such as Siemens, Omron, Schneider, Mitsubishi.

4) With BE rotating drum separator, high separating rate

5) All shot blasting machines are totally integrated with abrasive reclaim systems, separator and dust collector.

6) 20 years experienced engineers, customized service available.

7) After-sale service support will be provided within 24 hours.

Technical Parameters:

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

DX HIGH PERFORMANCE TURBINE

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.