Lowest Price for Q69 Steel Plate Roller Conveyor Shot Blasting Machine For Surface Cleaning

We insist over the principle of development of ‘High top quality, Performance, Sincerity and Down-to-earth working approach’ to supply you with exceptional services of processing for Lowest Price for Q69 Steel Plate Roller Conveyor Shot Blasting Machine For Surface Cleaning, Welcome all customers of home and abroad to go to our corporation, to forge a outstanding future by our cooperation.

We insist over the principle of development of ‘High top quality, Performance, Sincerity and Down-to-earth working approach’ to supply you with exceptional services of processing for Roller Conveyor Blasting Machine, Roller Conveyor Shot Blasting Machine, Roller Shot Blasting Machine, Our products and solutions are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

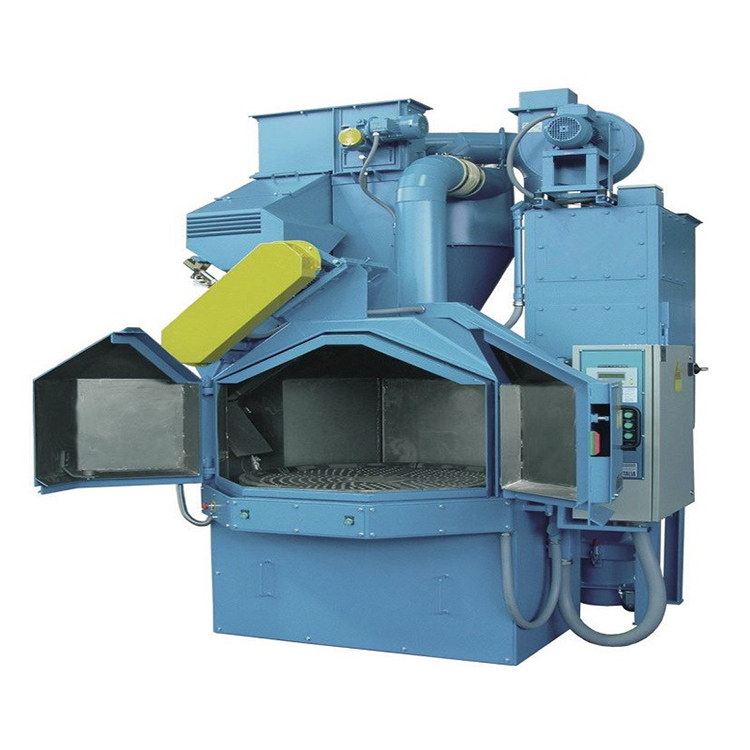

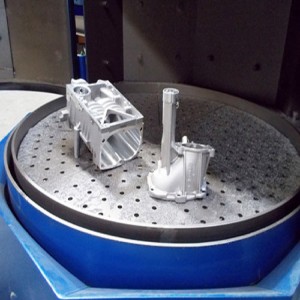

Hot Sale Rotating Table Cleaning Equipment from DX offer total flexibility in your shot blast operations. Whether you are cleaning welded fabrications, cleaning and deflashing castings, or shot peening components, the Rotary table, can help reduce the production time required.

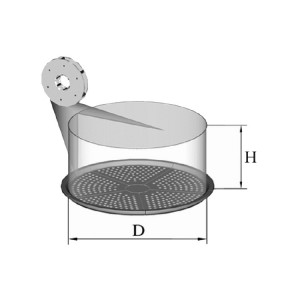

Technology parameter:

| Rotating Table Cleaning Equipment | ||||

| Item | DX356 | DX3510 | DX3516 | DX3518 |

| Max Work Diameter | 400mm | 1000 mm | 1500 mm | 2100 mm |

| Max Work Height | 400mm | 1000 mm | 1400 mm | 1800 mm |

| Table Diameter | 600 mm | 1200 mm | 1800 mm | 2500 mm |

| Max Load Capacity | 500 kg | 1000 kg | 2000 kg | 3000 kg |

| Blast Wheel, kw | 1*7.5 | 1*11 | 2*15 | 2*22 |

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

Applications:

- Cleaning

- Corrosion removal

- Cosmetic Finishing

- Deburring

- Deflashing

- Internal Cleaning

- Paint Stripping

- Preparation for Painting, Bonding and Plating

- Rust and Heat Scale Removal

- Shot Peening

- Surface Texturing

| Packing & Delivery: | ||

| 1 | Package | Standard package |

| 2 | Delivery time | 50 days after receiving the down payment |

| 4 | Quality Warranty | One Year |

| 5 | After-sales Service Provided | Engineers available to service machinery overseas |

FAQ:

1). Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2). Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3). Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4). Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

5). Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit.We have never got any complaint from our customers.

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.