What are the benefits of shot blasting for aluminum die castings?

Have a look in detail by following:

1, Shot Blasting has a high productivity

As a result of the use of a new type of shot blasting machine to 110 ~ 260 kg / min of the blasting volume, blasting speed of 50 ~ 75 m / s projectile blasting the work piece, in a few minutes to complete the clean-up. For larger or larger size of the work piece can be used multiple shot blasting device at the same time.

2, the surface of the parts to clean up, by color, decorative effect

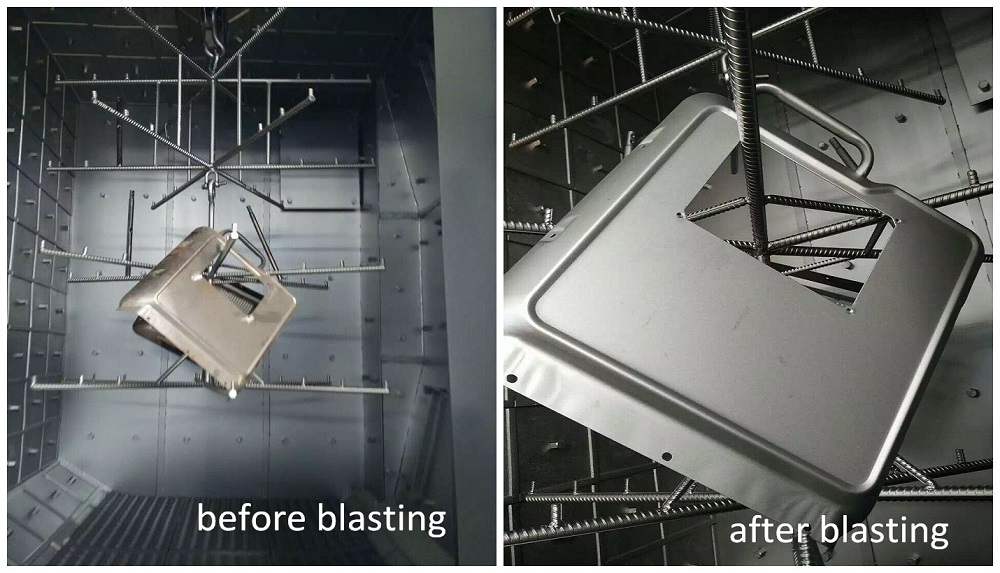

After the shot blasting treatment, can remove the attachment of the work piece surface, thin edge, flying wings, stains, eliminate scratches, so that the work piece presents the basic character.

3, to eliminate the surface stress concentration

Parts in the cooling process, due to uneven wall thickness, cooling rate is inconsistent, resulting in surface stress concentration. After the shot blasting, can improve the surface structure, to eliminate the surface stress (tensile stress) concentration, improve fatigue strength, and a slight increase in surface hardness.

4, increase the surface beauty

As the projectile is ball shot, projecting to the work piece to produce small concave hole, was spherical, like a concave mirror, in the light irradiation, such as the stars flashing, it is pleasing to the eye.

5, to improve the surface coating adhesion

After the shot blasting, the roughness can reach Ra1.6 ~ 6.3μm, the surface area is greatly increased, and the surface dirt is eliminated. Therefore, the adhesion of the surface is greatly enhanced when the surface is painted or other.

6, the process is simple, investment savings

As a result of dry shot blasting, and equipped with dust removal system, so after the shot blasting can be transferred to the next process, eliminating the need for liquid sandblasting and drying equipment required.

Post time: Jan-07-2019