Quots for Various Shape Sandblasting Equipment Water Internal Pipe For Abrasive Blast Clean Stainless Steel Spray Nozzle

Our personnel are often while in the spirit of “continuous improvement and excellence”, and using the exceptional good quality items, favorable rate and great after-sales products and services, we try to get just about every customer’s belief for Quots for Various Shape Sandblasting Equipment Water Internal Pipe For Abrasive Blast Clean Stainless Steel Spray Nozzle, Competitive value with top quality and satisfying company make us earned extra shoppers.we wish to work with you and request common development.

Our personnel are often while in the spirit of “continuous improvement and excellence”, and using the exceptional good quality items, favorable rate and great after-sales products and services, we try to get just about every customer’s belief for Internal Pipe Nozzle For Abrasive Blast Clean, Sandblasting Equipment Water Spray Nozzle, Stainless Steel Spray Nozzle, We are trying our best to make more customers happy and satisfied. we sincerely hope to establish a good long-term business relationship with your esteemed company thought this opportunity,based on equal, mutual beneficial and win win business from now till the future.

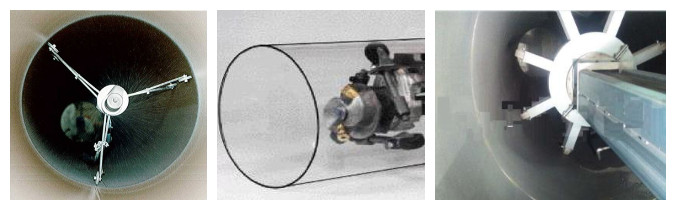

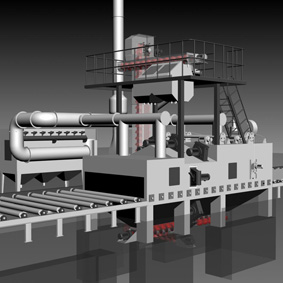

Steel Pipe Inner & Outer Shot Blasting Cleaning Machines are designed for the large, middle and small calibre size of the steel tube(outer and inner) and the cylinder. Impeller head locate at multi angle, This Steel Pipe Shot Blasting Machine is the high efficiency blasting wheels, shot blasting with high-speed thick blasting pills and blowing on the surface to have a tridimensional and omnibearing cleaning, to clean away the rusting layer, oxidation layer and other dirty things from surface quickly.

DX blast offers a range of roller conveyors from small simple machines to heavy duty machines and complete preservation lines, which can with 4,6,8,10,12 wheel units.

Machine Details:

1) The number and power of the turbines are chosen according to the requirement production rate.

2) PLC control system, stable quality and easy to get support from local.

3) Component key parts adopt world famous brand, such as Siemens, Omron, Schneider, Mitsubishi.

4) With BE rotating drum separator, high separating rate

5) All shot blasting machines are totally integrated with abrasive reclaim systems, separator and dust collector.

6) 20 years experienced engineers, customized service available.

7) After-sale service support will be provided within 24 hours.

Technical Parameters:

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

DX HIGH PERFORMANCE TURBINE

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.