Recycling Air Blasting Room - Automatic Air Blasting System with Belt Conveyor – DX-BLAST

Recycling Air Blasting Room - Automatic Air Blasting System with Belt Conveyor – DX-BLAST Detail:

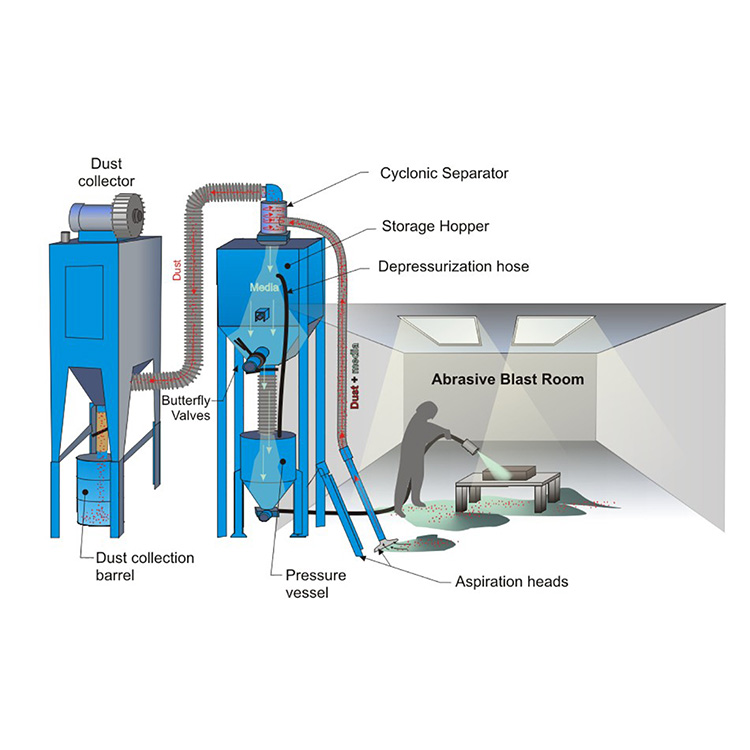

Robotic Air Blasting System with Belt Conveyor: the operator is inside the room during the blasting process. A protective suit and a helmet protect the operator from abrasive impact, and a fresh air supply provides sufficient ventilation through the blaster’s helmet.

Below size of blasting room is for customers’ reference. When you have different requirements, please let us know the size of blasting jobs, size of blasting room and quantity of spray guns, we can design blasting room according to your requirements.

Technology parameter:

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

FAQ:

1). Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2). Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3). Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4). Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

5). Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. We have never got any complaint from our customers.

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.

Product detail pictures:

Related Product Guide:

Porsche 911 Reimagined by Singer Vehicle Design Dynamics and Lightweighting Study | Tumble Belt Cast Parts Shot Blasting Machine

Global Sandblasting Machine Market | Research Detailed Report 2019-2023 (AB SHOT TECNIC, S.L,Blasting) and more… | Rotary Table Shot Blast Equipment

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Recycling Air Blasting Room - Automatic Air Blasting System with Belt Conveyor – DX-BLAST, The product will supply to all over the world, such as: France, Lithuania, Liverpool, We are committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.