Rotary Buffing Machine Surface Finishing For Metal Parts

All we do is always associated with our tenet ” Customer first, Trust first, devoting on the food packaging and environmental protection for Rotary Buffing Machine Surface Finishing For Metal Parts, The continual availability of significant grade merchandise in combination with our excellent pre- and after-sales support ensures strong competitiveness in an increasingly globalized market.

All we do is always associated with our tenet ” Customer first, Trust first, devoting on the food packaging and environmental protection for Buffing Machine, Metal Machine, Surface Finishing, Our skilled engineering group will always be ready to serve you for consultation and feedback. We’re able to also give you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and products. For anyone who is thinking about our company and merchandise, remember to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We’ll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

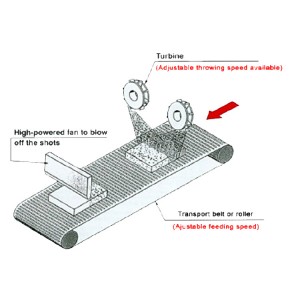

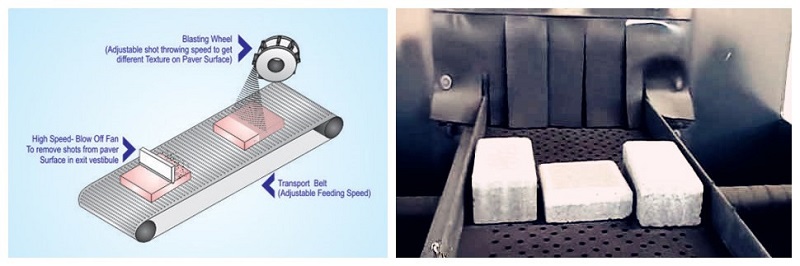

Stone and Ceramic Shot Blasting Machines are mainly used for surface roughening treatment of marbles, granites, concrete blocks. The working principle: different sized abrasive, thrown by the rapidly rotating blast wheel, is accelerated towards the surface being prepared.

Technology parameter:

DX Blast can provide a customized designed solution to fit your requirements with our engineering and production facilities and we’re so proud that our machines meet with a favorable reception from our customers.

FAQ:

1). Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2). Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3). Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4). Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

5). Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. We have never got any complaint from our customers.

Download:

If you have special requirements, please download Blasting Equipments Questionnaire for your reference.